Eddy Current Inspections

Eddy Current Method

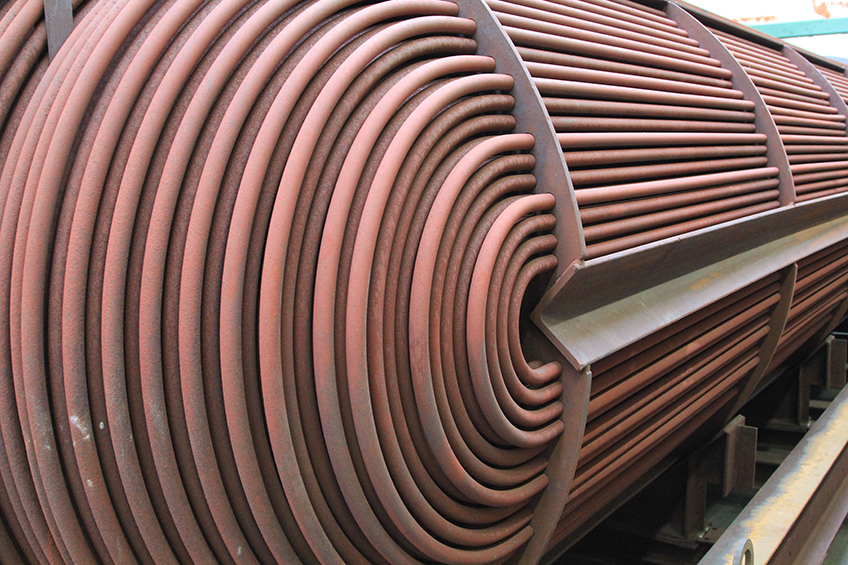

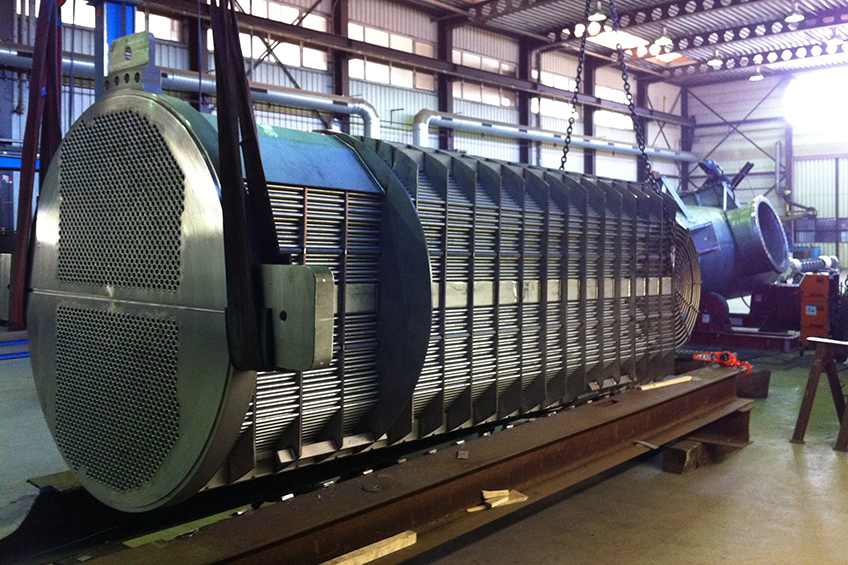

This is a method for inspection of non-ferromagnetic tubes in heat exchangers […]

Remote Field Inspection

RFT is primarily used to inspect ferromagnetic tubing since conventional eddy current techniques have difficulty inspection the full thickness of the tube wall […]

Magnetic Biased Eddy Current Inspection

The influence of permeability variations which accor with ferromegnetic materials has been reduced by using an eddy current probe with an integrated pre-saturation deive[…]

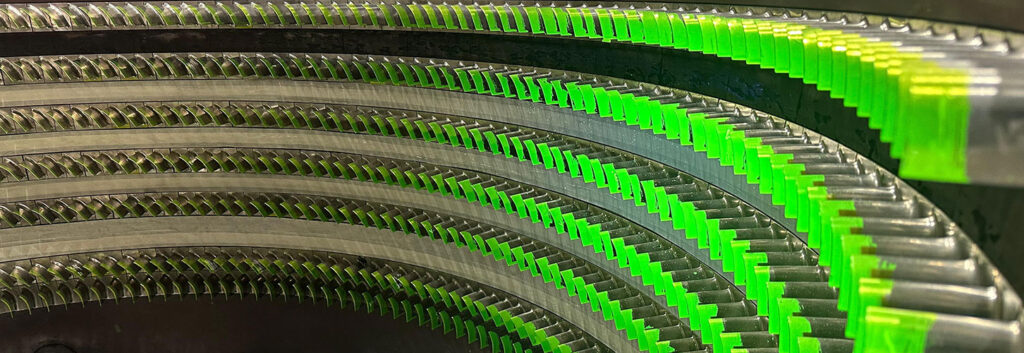

Surface Testing

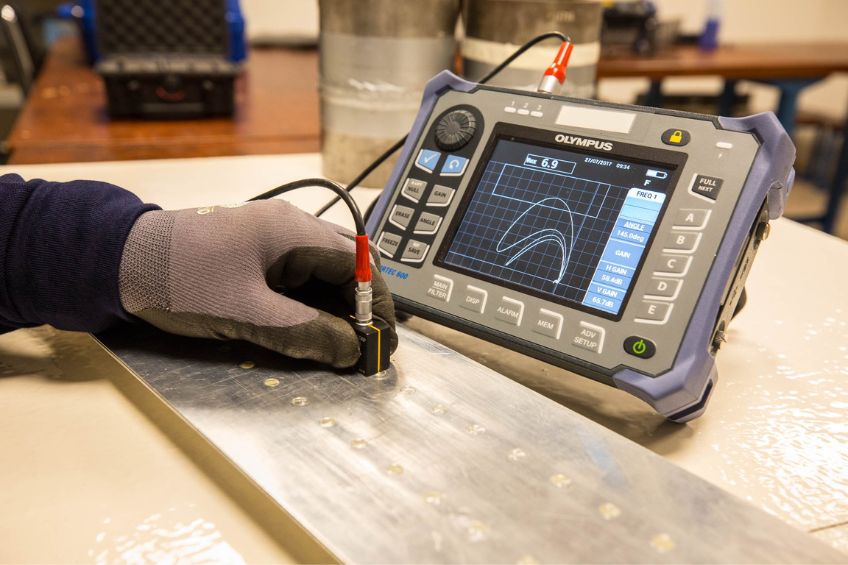

Surface eddy current testing is used for detection of surface cracks in both non-ferromagnetic and ferromagnetic materials […]

Weld Inspection

In welding inspection there is a need to detect surface breaking defects. For magnetic material e.g. carbon steel, generally magnetic particle inspection is used […]

Other Eddy Current Inspections

Coating thickness measurements | Clad overlay | Material selection

Standard Non Destructive Testing

Ultrasonic Testing

Ultrasonic testing uses high-frequency sound energy to perform examinations and make measurements […]

Magnetic Particle Inspection

This inspection method is used for detecting surface breaking defects in ferromagnetic materials […]

Dye Penetrant Inspection

This method is used to find surface breaking defects. Penetrant Testing can be done on a wide variety of materials, but it is mainly used on non-ferrous metals […]

Visual Inspections

Visual Inspections – Endoscopy

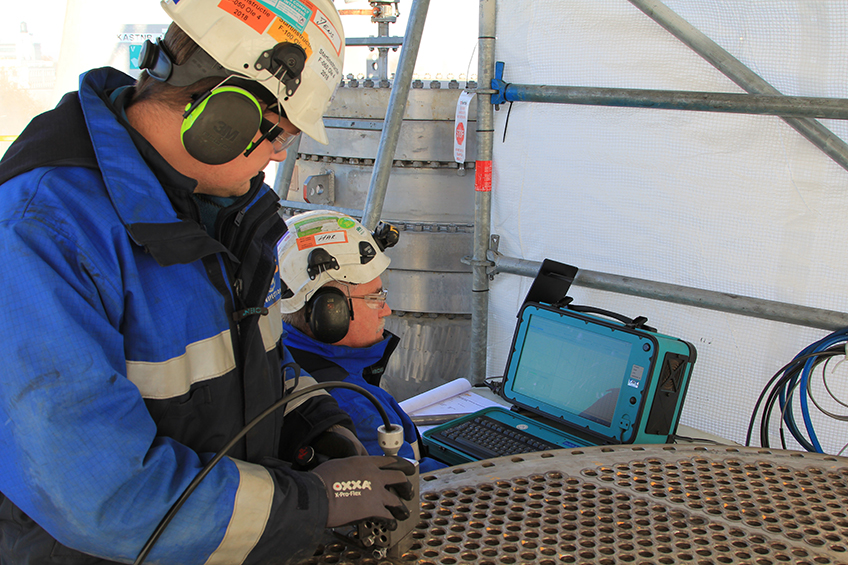

JSC Performs visual and remote visual (endoscopy) inspections. JSC Inspections has several video and boroscopes for internal inspections […]

Other Inspection Techniques

Other Inspection Techniques

Crack depth measurement | Ferrite content measurement | Pinhole/porosity testing coating | Nelson hydrogen attack measurements […]

Specials

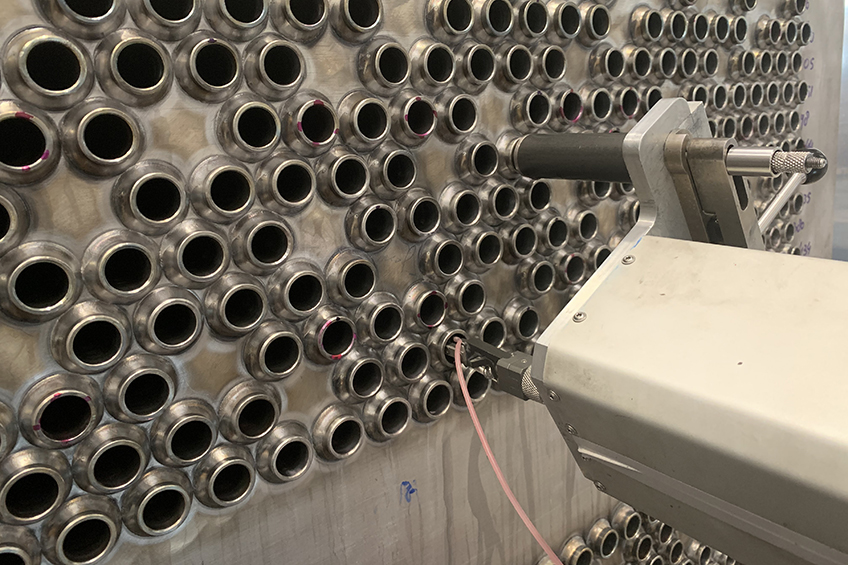

Tube-to-tubesheet weld inspection

The inegrity of tube-to-tube-sheet welds in heat exchangers in chemical industries of vital importance for untroubled service reliability […]

Reformer Tube Creep measurements

Eddy Current crack testing and creep detection by laser. One of the most important tasks for a reliable operation of reformer furnaces is the integrity of the reformer tubes[…]

![Eddy Current crack testing and creep detection by laser. One of the most important tasks for a reliable operation of reformer furnaces is the integrity of the reformer tubes[...]](https://jscinspections.nl/wp-content/uploads/2018/03/Reformer-Tube-Creep-measurement-2-1.jpg)