Reformer Tube Creep measurements

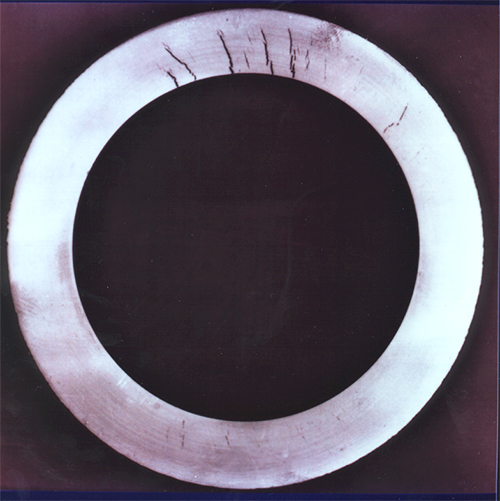

Eddy Current crack testing and creep detection by laser

The integrity of the reformer tubes is of vital importance to provide reliable operation settings. The early detection and monitoring of creep damage and micro-cracks can prevent unnecessary surprises and improve reformer operation, furnace balance, tube replacement planning and prevent unplanned shut-downs.

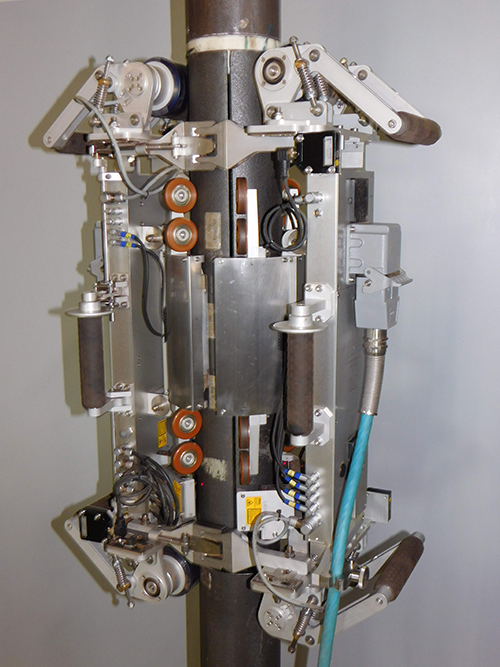

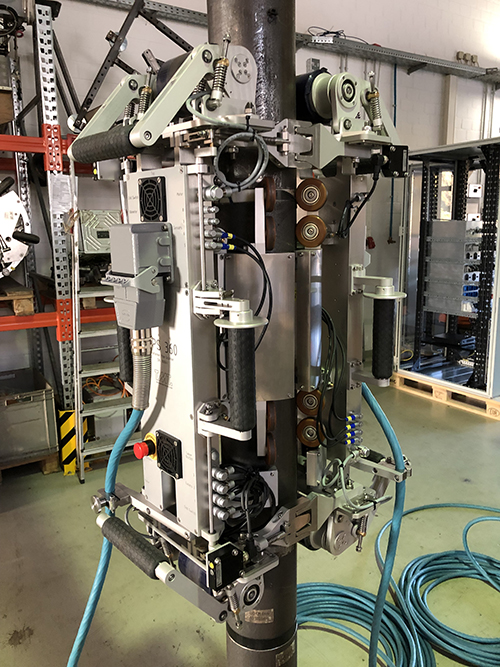

External inspection

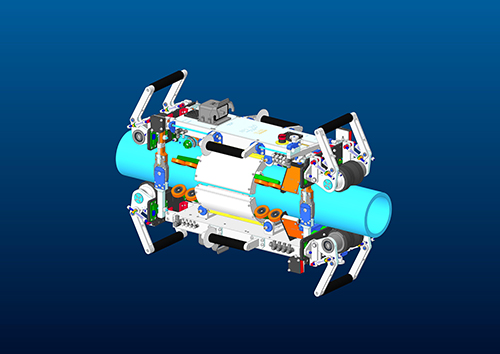

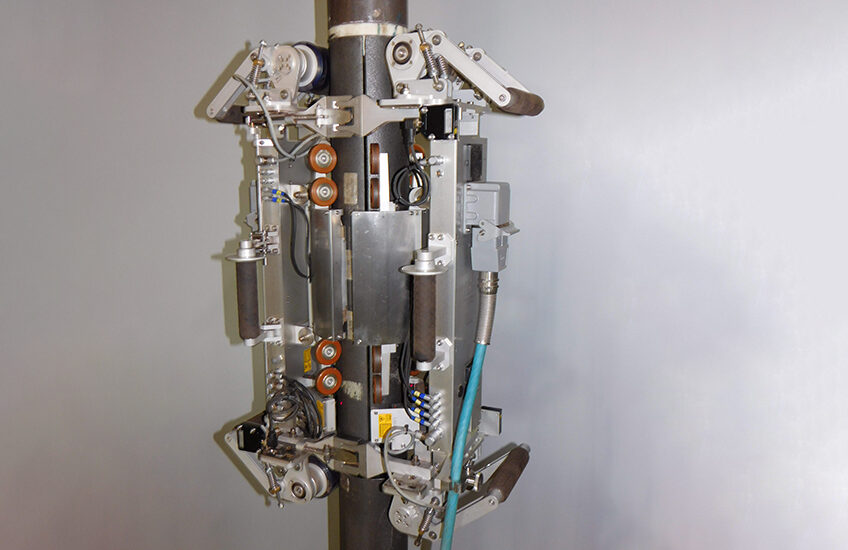

The reformer scanner is equipped with a powerful multi-channel probe array for crack detection is reformer tubes up to 23 mm in wall thickness. Compared to the ultrasonic inspection technique also used for creep damage detection, ECT lacks the need for couplant, increasing the inspection speed. Diameter measurement performed by a laser is done simultaneously with the eddy current testing. The complete unit is moved by a remote-controlled crawler unit allowing the the passage from the furnace floor to the roof assuring a fast and reliable inspection.

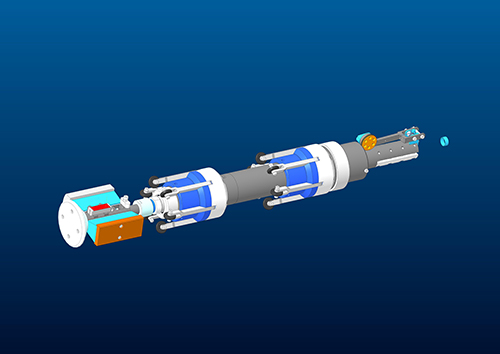

Internal inspection

When the catalyst has been removed an internal rotary laser and eddy current system is used for the internal inspection.

The key benefits:

- Accurate, robust and reliable data acquisition

- Powerful multi-channel probe array for crack detection

- Integrated laser module for creep damage detection

- High inspection speed

- Accurate location and sizing features

- High repeatability allowing indication monitoring

- On-site reporting

JSC Inspections – we offer Non-Destructive Testing and Inspection Services for clients in the oil-, gas- and petrochemical industries, the chemical industry, the energy sector and the construction of pipelines and structures industry.