Dye Penetrant Inspection

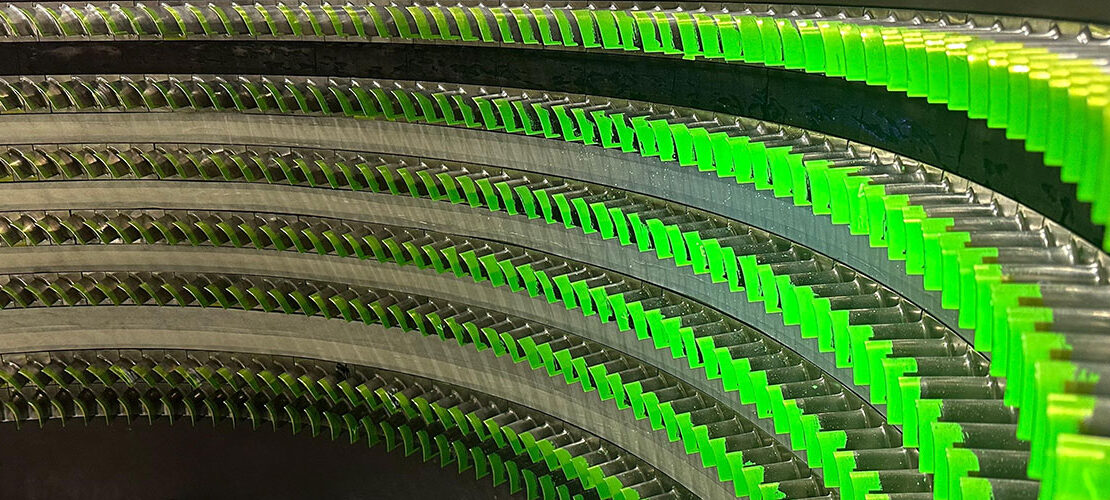

This method is used to find surface breaking defects. Dye penetrant testing can be done on a wide variety of materials. This inspection is based upon the capillary action, low surface tension fluid penetrates into clean and dry surface breaking discontinuities. After adequate penetration, the excess penetrant is removed and a developer is applied. The developer extracts the penetrant out of the flaw. Because of the high contrast between the developer and dye, the indication can be visually detected by the inspector. For more sensitive dye penetrant testing inspections, a fluorescent dye can be used. This is usually done when the defects are very small >2mm.

JSC Inspections – we offer Non-Destructive Testing and Inspection Services for clients in the oil-, gas- and petrochemical industries, the chemical industry, the energy sector and the construction of pipelines and structures industry.